The design of an engine frame for battery electric propulsion

Project DragonFly has been started with the goal to complete the build of the existing Viking Dragonfly MK.II while transforming the airplane into a cleaner, quieter and smarter solution. Initial studies have demonstrated that Project DragonFly is viable and plans have been made to finish the primary structure of the Dragonfly. The next step on the roadmap to complete the build of the Dragonfly is to design the engine mount for an electric propulsion configuration. Its main function is to attach the engine to the body of the plane while being able to distribute the weight of batteries and the engine and to absorb the vibrations and torque generated by the engine. Aeronautical Engineering graduate student Luca Baak is responsible for this important task and defined the following main research question:

“What is the most suitable design of an engine mount for the electric Viking DragonFly MK.II taking into consideration strength, stiffness, material, costs and manufacturing requirements?”

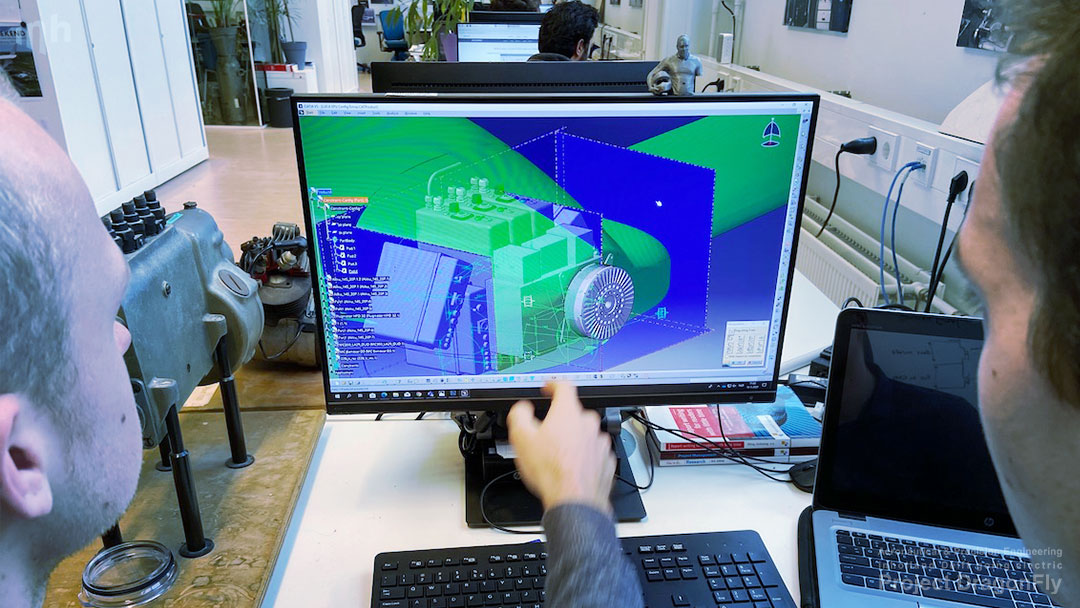

Luca Baak presents geometrical limitations of an electric propulsion configuration (concept) in the cowling.

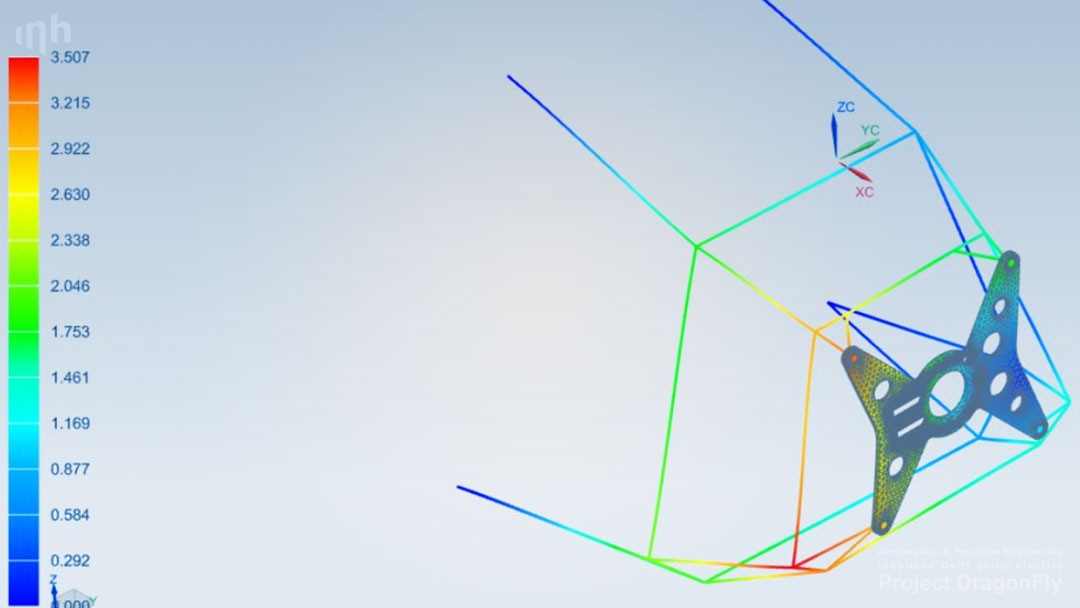

First analysis of the conceptual design of an engine frame for the electric Viking Dragonfly mk.II; ready to be optimized.

This research focusses on creating a verified design of an engine mount for the Dragonfly, which includes design activities, FEM analyses and defining the production process. The Aeronautical & Precision Engineering department at Inholland University of Applied Sciences recently obtained Siemens software, which is fully integrated into our Digital Twin strategy. Hence, Luca is using Siemens NX and Nastran NX to model concepts, perform FEM analyses and optimize towards a final design.

As one of the pioneers of the integration of Siemens software within Inholland, Luca emphasizes on project challenges: “The essence of this research is to demonstrate the technology and procedure to design an efficient and reliable engine frame. Given that a significant amount of airplanes are viable to be converted to electric propulsion, these type of activities shall be performed regularly in the nearby future. The design of an engine frame using Siemens NX and Nastran NX phases various challenges. (1) As I am the first one working with Siemens NX and Nastran NX in the team of Project DragonFly, a verification study shall be performed to eliminate user errors and ensure that the simulation output is realistic. I included a verification study, where a NACA wing profile is simulated and compared to theoretical calculations. (2) Another challenge is that batteries, motors and other components must be replaceable. (3) In addition, the design of the electric propulsion system is still iterating. This means that the engine frame should be usable for various battery and engine configurations. These requirements, and many other customer and regulatory requirements, are considered for the final engine frame design that will be published in July 2020.”