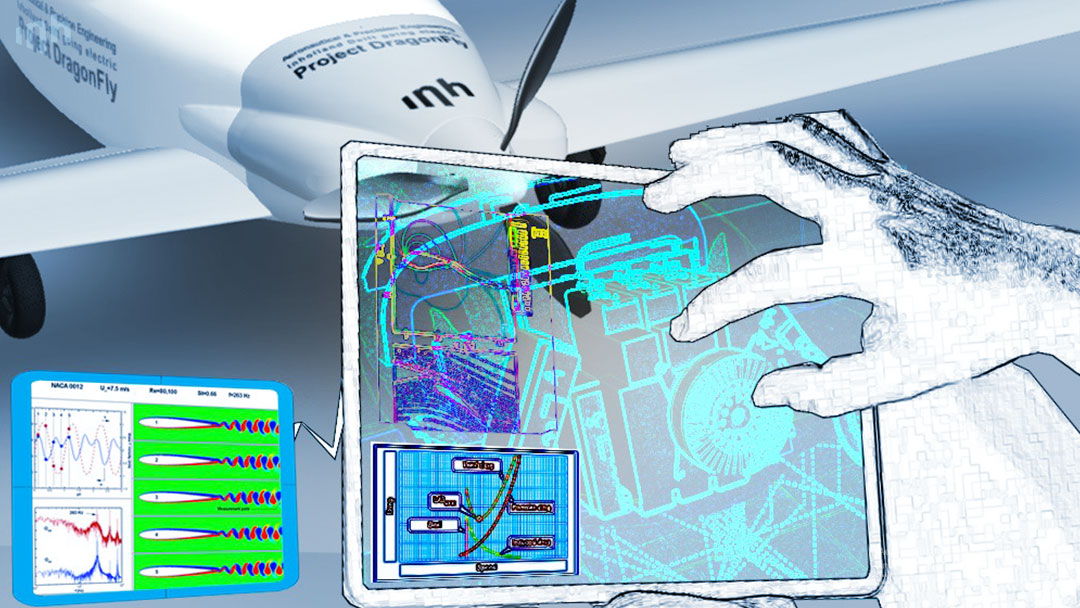

Mixed Reality application for smart visualization

The next step in the roadmap is developing a Digital Twin of the electric DragonFly airplane bridging the physical and virtual world. The Digital Twin provides smarter solutions to potentially be smarter and more efficient in the iterative process of design, build and test products such as airplanes.

“The Mixed Reality application is a smart and efficient method to share information between students, researchers and the industry. The virtual designs can be compared to the physical state of the airplane, which is very useful to share the current state of Project DragonFly. This technology is ready to be implemented in the Digital Twin strategy and has a huge potential in the development of aircraft systems.”, said Kiril Medarov, who created the first version of the Mixed Reality application for Project DragonFly during his internship from September 2019 to January 2020.

Researchers Didier Dorival and Jonas Rieder proceed on Kiril his deliverables. In collaboration with DutchVR, the Mixed Reality application has been further developed for educational activities, exhibitions, company visits and transfer of information between project members. The first design of the electric propulsion system will be presented while graphs and figures substantiate related decisions. Also relevant aerodynamics and performance characteristics of the Dragonfly airplane are visualized in this application. The first version of the updated application will be published in June 2020.

Conceptual design of aircraft design and data visualization using Mixed Reality.

Didier Dorival, who has years of experience in composite repair, explains another potential for this technology: “Besides visualizing latest designs in a digital twin format, it is also applicable to the MRO business for existing aircraft. There is a need in the composite repair industry to inspect and prepare repairs remotely as this reduces the amount of repair specialists that need to be facilitated at the location where defect airplanes are grounded, thus saves lots of effort and money. The application for Project DragonFly will demonstrate how composite defects can be visualized, using acoustic inspections, in a smart and efficient way, such that repair strategies can be designed from anywhere in the world. More information about research on automation of composite repair can be found on https://projectfixar.nl/ (to be released in summer 2020).”

Conceptual design of visualizing structural defects using Mixed Reality.